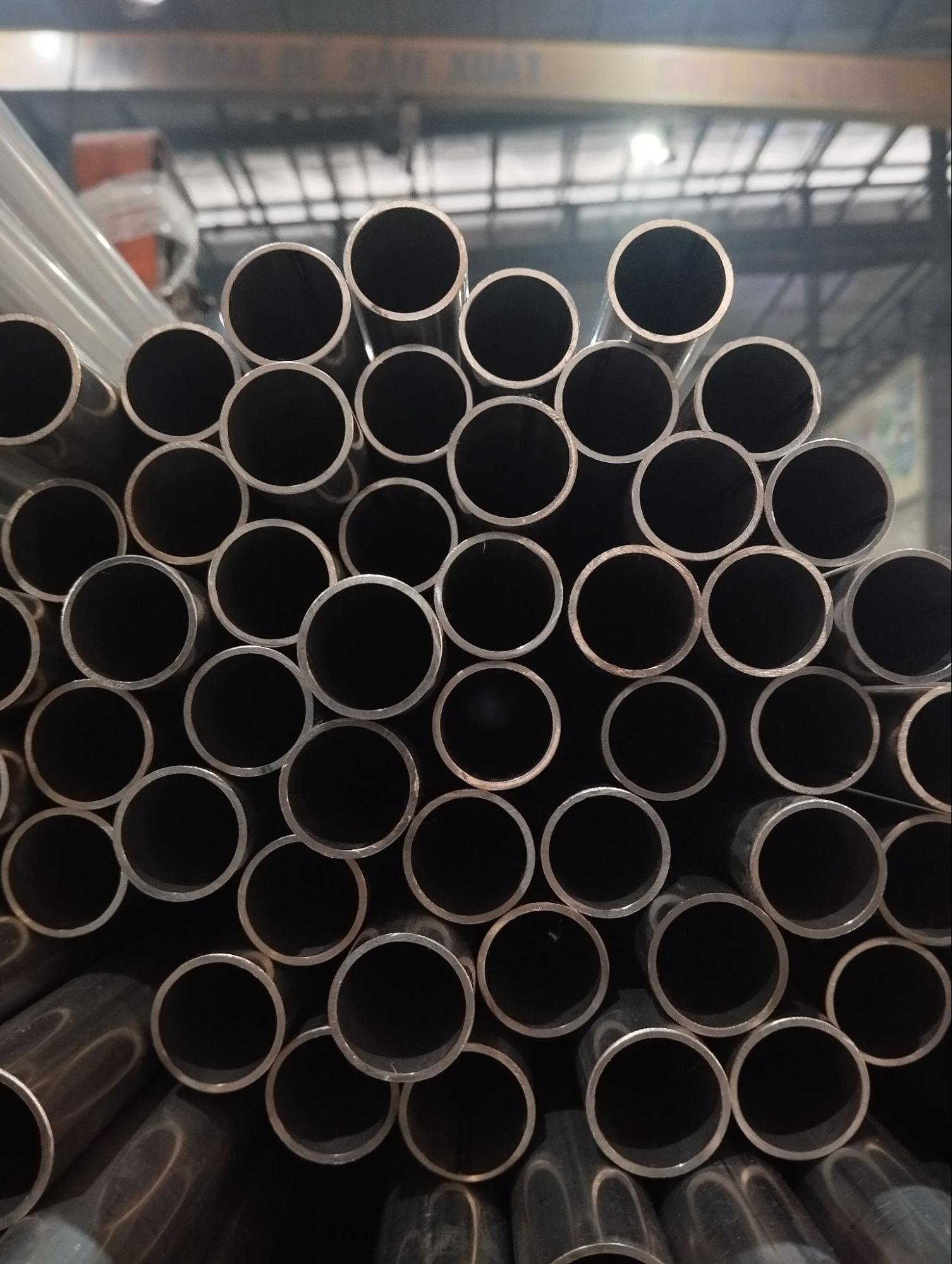

Which Type of Stainless Steel Pipe Is the Best? A Guide to Choosing the Right One for Your Application

Stainless steel pipes are widely used across many industries thanks to their durability and excellent corrosion resistance. However, the wide variety of stainless steel grades such as 201, 304, and 316 often raises the question: Which type of stainless steel pipe is the best? In reality, there is no single “best” stainless steel pipe for all applications. The right choice depends on the operating environment, technical requirements, expected service life, and budget. In this article, Son Ha SSP will help you understand the key evaluation criteria, compare common types of stainless steel pipes, and avoid common mistakes when making a selection.

1. Criteria for Determining High-Quality Stainless Steel Pipes

To accurately answer the question “Which type of stainless steel pipe is the best?”, it is first necessary to clearly define the quality assessment criteria.

1.1 Durability and Corrosion Resistance

Corrosion resistance is the most critical factor when evaluating the quality of stainless steel pipes, as it directly affects product durability and service life during use. This property mainly depends on the chemical composition of the stainless steel, particularly the content of chromium (Cr), nickel (Ni), and other alloying elements.

Criteria for Determining High-Quality Stainless Steel Pipes

Chromium plays a key role in forming a passive oxide layer on the surface of stainless steel pipes, helping to prevent oxidation and limit the impact of the external environment. The higher the chromium content, the more significantly rust resistance and corrosion resistance are improved. Meanwhile, nickel enhances ductility, mechanical strength, and corrosion resistance in humid or mildly corrosive environments.

For harsher conditions such as coastal areas, chemical environments, or locations frequently exposed to saltwater, some high-grade stainless steels are additionally alloyed with molybdenum (Mo). This element helps improve resistance to localized corrosion, pitting, and surface attack, while maintaining material stability over long-term use.

Depending on the actual operating environment—such as indoor use, outdoor exposure, high-humidity areas, or chemical environments—the required level of corrosion resistance for stainless steel pipes will vary. Therefore, a stainless steel grade that performs well under normal conditions may not be suitable for more aggressive environments. Properly assessing corrosion resistance from the outset helps ensure the selection of the right stainless steel pipe, guaranteeing durability and long-term performance for the project.

1.2. Service Life and Long-Term Stability

The service life of stainless steel pipes depends not only on the steel grade used but is also influenced by many other technical factors during manufacturing and use.

Pipe wall thickness is a critical factor in determining load-bearing capacity, pressure resistance, and long-term stability. Stainless steel pipes with appropriate wall thickness help minimize denting, deformation, or cracking over time.

Welding technology and weld treatment also have a direct impact on the service life of stainless steel pipes. Properly executed welds with uniform surfaces and good post-weld treatment help reduce the risk of localized corrosion, leakage, or cracking at joints—common weak points in low-quality stainless steel pipes.

In addition, material quality, manufacturing processes, installation conditions, and actual operating practices all significantly affect the lifespan of stainless steel pipes. Proper installation, avoidance of strong impacts, operation within designed load limits, and regular maintenance will help extend the service life of the product.

Pipe wall thickness, welding technology, and manufacturing conditions directly affect the quality of stainless steel pipes.

A standard-compliant stainless steel product will offer high stability, with minimal deformation, cracking, or degradation over long-term use. In contrast, low-quality stainless steel pipes that are impure or fail to meet technical standards may quickly suffer from localized corrosion, reduced strength, and compromised safety, directly affecting the durability and lifespan of the structure.

1.3. Suitability for the Intended Application

A common misconception is that the “higher-grade” the stainless steel, the better it is in all cases. In reality, selecting stainless steel pipes should be based on the specific application, such as:

- Interior decoration

- Structural construction

- Domestic water supply

- Industrial manufacturing, food processing, or chemical applications

Using overly high-grade stainless steel for simple applications can lead to unnecessary investment costs, while choosing an unsuitable grade for harsh environments may pose risks to durability and safety.

A luxurious space achieved by using stainless steel as the primary material.

2. Comparison of Common Stainless Steel Pipes on the Market Today

Currently, the three most commonly used types of stainless steel pipes are stainless steel 201, 304, and 316. Each type has its own characteristics and is suitable for specific needs.

2.1. Stainless Steel 201 Pipes

Stainless steel 201 pipes have a lower nickel content compared to stainless steel 304 and 316, and manganese is substituted for some of the nickel to reduce costs. This change in composition makes stainless steel 201 more price-competitive and suitable for projects with limited budgets.

- Advantages: Stainless steel 201 has a bright surface finish, meeting aesthetic requirements for decorative applications.

- Limitations: The main drawback of stainless steel 201 is its only moderate corrosion resistance. In humid environments, outdoor conditions, or areas exposed to mild chemicals, stainless steel 201 may rust if not properly maintained and used. Therefore, it is not suitable for projects requiring high long-term durability.

- Applications: Stainless steel 201 pipes are commonly used for interior decoration, indoor constructions, dry environments, or locations that do not frequently come into contact with water or chemicals.

2.2. Stainless Steel 304 Pipes

Stainless steel 304 pipes are considered the most widely used type today due to their well-balanced combination of quality, durability, and investment cost. With higher chromium and nickel content than stainless steel 201, stainless steel 304 offers good corrosion resistance in most standard operating environments.

Stainless Steel 304 Pipe

- Advantages: Stainless steel 304 offers high durability, stable service life, and good rust resistance in humid conditions and moderately harsh outdoor environments. In addition, stainless steel 304 is highly regarded for its safety, making it suitable for use in food processing, domestic water systems, and industries with strict hygiene requirements.

- Limitations: Stainless steel 304 pipes are more expensive than stainless steel 201 and are not the optimal choice for long-term exposure to strong chemical environments or saltwater. Under such conditions, stainless steel 304 may still be subject to corrosion if appropriate protective measures are not applied.

- Applications: Stainless steel 304 pipes are widely used in water supply and drainage systems, railings, staircases, stainless steel structures, light industries, and food processing applications.

2.3. Stainless Steel 316 Pipes

Stainless steel 316 is a premium-grade stainless steel that contains added molybdenum to significantly enhance corrosion resistance compared to stainless steel 304. This element enables stainless steel 316 to withstand corrosion caused by chemicals, salt, and harsh environmental factors.

- Advantages: Stainless steel 316 pipes provide excellent corrosion resistance in chemical environments, saltwater, and coastal areas. They offer high durability, maintain stability under harsh operating conditions, and meet stringent technical standards in many specialized industries.

- Limitations: The higher cost results in greater initial investment compared to stainless steel 201 and 304. For common applications, using stainless steel 316 may be unnecessary and lead to higher costs without proportional benefits.

- Applications: Commonly used in coastal construction projects, chemical industries, medical equipment, and high-requirement food processing sectors where hygiene, safety, and long-term durability are critical.

| Criteria | Stainless Steel 201 | Stainless Steel 304 | Stainless Steel 316 |

| Composition | Cr: 16–18%Ni: 3.5–5.5%Mo: None | Cr: 18–20%Ni: 8–10.5%Mo: None | Cr: 16–18%Ni: 10–14%Mo: 2–3% |

| Corrosion resistance | Moderate | Good | Excellent |

| Resistance to humid environments | Moderate | Good | Excellent |

| Resistance to chemicals / saltwater | Poor | Moderate | Excellent |

| Durability and service life | Moderate | High | Very high |

| Food safety suitability | Not recommended | Suitable | Suitable |

| Cost | Low | Medium | High |

| Typical applications | Interior decoration, dry environments | Residential, light industrial | Chemical, medical, coastal |

Technical Comparison of Common Stainless Steel Pipes

3. Common Mistakes When Choosing the “Best” Stainless Steel Pipe

When searching for the best stainless steel pipe, many people make common mistakes due to limited technical knowledge or reliance on initial impressions. Typical errors include:

- Comparing price only while ignoring technical standards: Price differences are influenced not only by steel grade but also by wall thickness, manufacturing technology, inspection standards, and material quality. Choosing cheaper, non-compliant products can lead to serious risks during use.

- Believing that “all stainless steel is rust-proof in all conditions”: This is inaccurate. Corrosion resistance depends heavily on chemical composition and operating environment. Selecting the wrong grade can still result in corrosion over time.

- Failing to distinguish standard-compliant stainless steel from low-quality or mixed alloys: Inferior stainless steel often has poor corrosion resistance, unstable strength, and is prone to rust after a short period. Not checking origin, certifications, and standards may lead to substandard purchases.

- Choosing the wrong grade for the operating environment: For example, using stainless steel 201 outdoors or in high-humidity areas increases the risk of rust and reduces service life. Correctly identifying the environment from the outset is critical.

- Overlooking pipe wall thickness and weld quality: These factors directly affect load-bearing capacity, tightness, and long-term stability. Poor welds or uneven thickness can cause cracking, leakage, and reduced structural safety.

4. Suppliers of High-Quality Stainless Steel Pipes

In addition to selecting the right stainless steel grade, the supplier plays a crucial role in ensuring product quality. A reputable supplier should meet the following criteria:

- Clear product origin and traceability

- Full compliance with technical standards and quality certifications

- High uniformity in wall thickness, surface finish, and dimensions

- Professional consultation based on actual usage needs, not simply selling the most expensive option

- Transparent warranty and after-sales policies

Son Ha SSP supplies the full range of the best stainless steel pipe products on the market.

Currently on the market, Son Ha SSP Vietnam One Member Limited Liability Company is one of the stainless steel pipe suppliers trusted by many partners. With a modern manufacturing system, clearly defined technical standards, and stable supply capability, Son Ha SSP not only offers a wide range of stainless steel products—such as decorative stainless steel pipes, industrial stainless steel pipes, and cold-rolled coils—but also focuses on providing tailored solutions for specific usage needs. This is a key factor in ensuring quality, durability, and long-term efficiency for construction works and projects.

If you are looking for a reliable supplier of high-quality stainless steel pipes, please contact us via Hotline 1800 6566 or visit sonhassp.com. Our team will get in touch and provide consultation as soon as possible.

So, which type of stainless steel pipe is the best? The answer depends on the intended application, installation environment, and investment budget. Rather than searching for a single “absolutely best” product, users should aim for the most suitable option. Understanding the characteristics of each type and making the right choice from the beginning will help optimize costs, extend project lifespan, and minimize risks during use.

>> RELATED ARTICLES:

A Detailed Overview of the Characteristics and Applications of Welded Stainless Steel Pipes

SON HA INDUSTRIAL STAINLESS STEEL PIPES – THE PERFECT SOLUTION FOR EVERY PROJECT

Son Ha SSP Vietnam Shines at the World Stainless Steel Conference & Exhibition 2025 – Netherlands

Next latest post

Safe Stainless Steel Pipe Transportation Process and Important Considerations

What Is a Ø16 Stainless Steel Pipe? Specifications, Classification, and the Latest Price List

Son Ha SSP Is Honored to Receive the BIS Certification (India)