What is Martensitic stainless steel? Characteristics of Martensitic stainless steel

The term “Martensitic stainless steel” has long been recognized as a unique alloy in the industrial and construction sectors due to its impressive characteristics. In this article, Son Ha SSP will provide readers with a deeper understanding of this remarkable material.

What is Martensitic Stainless Steel

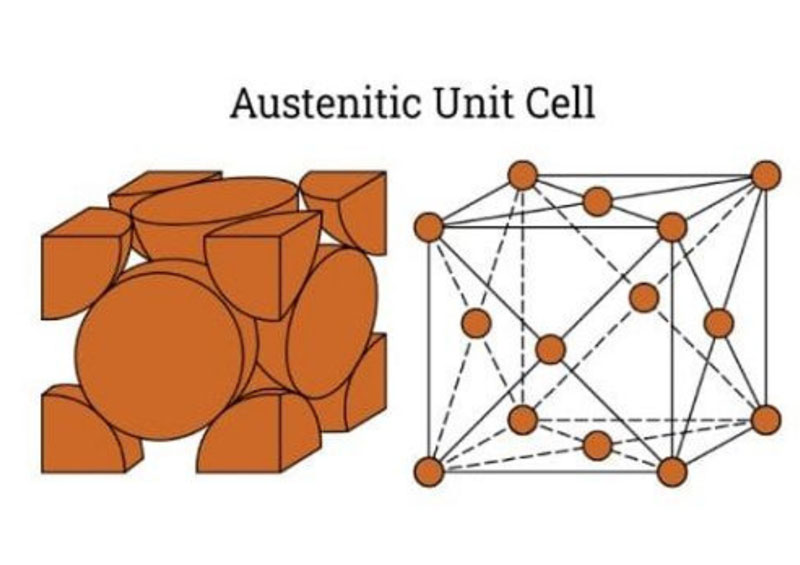

Martensitic stainless steel is a type of stainless steel belonging to the Martensitic group. It is an alloy with a specific crystalline structure that undergoes transformation during the martensitic heat treatment (quenching) process. Martensitic stainless steel is developed based on an alloy of Chromium (typically from 10.5% to 18%) and Carbon (from 0.1% to 1.2%). The Chromium content in Martensitic stainless steel is directly proportional to its corrosion resistance.

Inox Martensitic

Martensitic stainless steel is often alloyed with elements such as Boron (B), Cobalt (Co), Niobium (Nb), and Titanium (Ti) to improve high-temperature properties, especially creep resistance.

Notable Properties of Martensitic Stainless Steel

Martensitic stainless steel possesses several characteristic properties that make it an ideal material in various applications. Specifically:

High Hardness: Due to its high carbon content and heat treatment capability, Martensitic stainless steel can achieve exceptional hardness, with HRC (Hardness Rockwell C) values typically ranging from 50-60 HRC, depending on the alloy grade and heat treatment process. Its impressive hardness is attributed to the unique crystalline structure resulting from the martensitic heat treatment (quenching).

Due to its special crystalline structure, Martensitic stainless steel is an ideal material in many applications

Good Tensile Strength: The tensile strength of Martensitic stainless steel ranges from 600 to 1200 MPa. This is an estimated value depending on the specific material within this group.

Moderate Wear Resistance: Martensitic stainless steel, with its crystalline structure consisting of twinned regions and mechanical deformation, creates a hard surface and effective wear resistance, helping to resist sliding, impact, and the effects of hard particles. However, compared to Austenitic stainless steel (such as 304 and 316), its corrosion resistance is lower but still performs well in mild environments such as air and fresh water.

Customizability: The martensitic heat treatment (quenching) process is used to optimize the mechanical properties of Martensitic stainless steel, flexibly meeting various requirements in specific applications. By adjusting temperature and time, the material can be transformed to achieve mechanical properties such as hardness, toughness, or wear resistance, suitable for specific purposes.

Comparison of Martensitic Stainless Steel with Other Stainless Steel Types

To better understand the characteristics of Martensitic stainless steel, let’s compare it with two other common stainless steel groups: Austenitic and Ferritic.

| Characteristic | Martensitic Stainless Steel | Austenitic Stainless Steel (304, 316) | Ferritic Stainless Steel (430) |

| Main Composition | Crom (10.5%-18%), Carbon (0.1%-1.2%) | Crom (16%-26%), Nickel (8%-20%) | Crom (16%-18%), very little or no Nickel |

| Hardness | High, can reach 50-60 HRC | Lower, cannot be hardened by heat treatment | Medium, cannot be hardened by heat treatment |

| Corrosion Resistance | Moderate | Very good | Good, but less than Austenitic |

| Machinability | Easy to machine when annealed, harder when hardened | Easiest to machine | Medium |

| Main Applications | Cutting tools, cutlery, load-bearing valves | Kitchenware, medical equipment | Household appliances, interior decoration |

⇒ See more: Industrial Stainless Steel Pipes: Advantages and Applications

Applications of Martensitic Stainless Steel

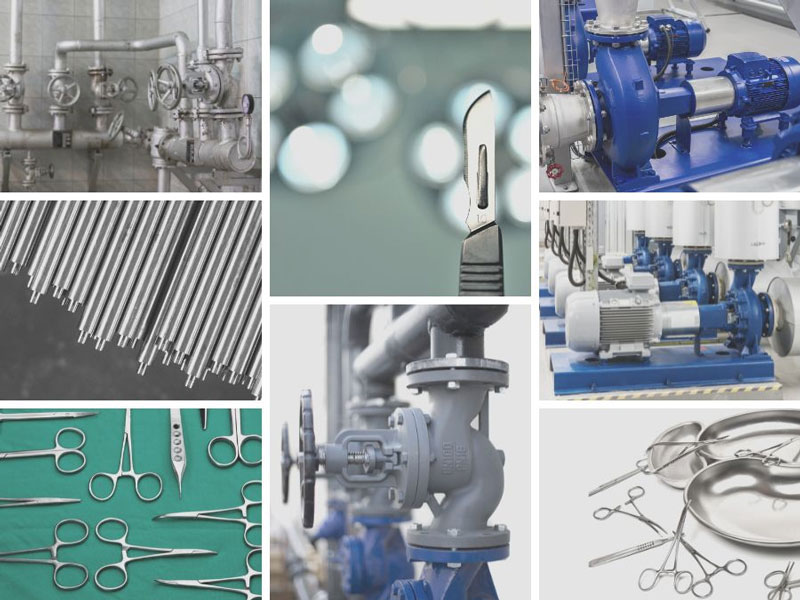

Depending on the carbon content, Martensitic stainless steel will be applied in different cases. For example, if the carbon content in the stainless steel reaches about 0.4%, it will usually be used mainly in applications such as pumps, valves, and shafts. If the carbon content is above 0.4% C, they are used primarily for wear resistance, such as in surgical blades, plastic molds, and nozzles. Specifically:

Cutting Tool Production: It is estimated that about 70% of cutlery and cutting tools worldwide are made from Martensitic stainless steel. This is because Martensitic stainless steel has a hardness of up to 60 HRC. Therefore, products such as knives, scissors, and saw blades will always maintain long-lasting sharpness and are less prone to wear over time.

Machinery Manufacturing: In the production of machinery and industrial equipment, Martensitic stainless steel is used in components subjected to high loads and pressures. Specifically, these include components: gears in machine transmission systems, pump shafts in the oil and gas industry and machine manufacturing industry, and pressure-resistant industrial valves (ball valves, gate valves).

Applications of Martensitic Stainless Steel

Watchmaking: Martensitic stainless steel is often used in the production of watch components such as bearings and spring mechanisms. Its ability to maintain sharpness and high hardness helps maintain the accuracy and operation of watches.

Automotive Manufacturing: Martensitic stainless steel is used in components requiring high strength and hardness such as engine parts, suspension components, and chassis. The material’s properties help improve the performance and durability of components.

Energy Industry: Martensitic stainless steel is also used to make hydroelectric turbine blades, pump shafts, and pressure-bearing equipment in energy production systems. According to statistics, more than 20% of hydroelectric turbines worldwide use components made from Martensitic stainless steel to ensure high lifespan and stable operation.

Other Industrial Applications: In addition to the above applications, Martensitic stainless steel is also used in the production of other industrial components such as fan shafts in aircraft engines, gears in military transmission systems, or meat grinders and blades in industrial grinders.

The above is detailed information about Martensitic stainless steel – an important material with many outstanding applications in life and industry. If readers need more specific advice on the properties, advantages, or applications of Martensitic stainless steel, please do not hesitate to contact Son Ha SSP through the website: sonha.com.vn or via hotline 1800 6566 for the fastest and most accurate support!

Next latest post

Safe Stainless Steel Pipe Transportation Process and Important Considerations

What Is a Ø16 Stainless Steel Pipe? Specifications, Classification, and the Latest Price List

Son Ha SSP Is Honored to Receive the BIS Certification (India)