Overview of Corrosion-Resistance Standards for Stainless Steel Welded Pipes

Stainless steel pipes (commonly known as inox) are widely used across industries that require high corrosion resistance. Although stainless steel naturally resists oxidation thanks to its chromium content, it can still suffer from corrosion in harsh environments if technical requirements are not met.

Therefore, corrosion-resistance standards for welded stainless steel pipes were established to clearly define chemical composition, mechanical properties, and production processes to ensure consistent product quality.

So, what are the key corrosion-resistance standards for welded stainless steel pipes? Let’s explore them below.

1. Corrosion-Resistance Standards for Stainless Steel Welded Pipes

1.1. ASTM Standards

ASTM (American Society for Testing and Materials) is the most widely used international system for evaluating the quality of welded stainless steel pipes. Among these, ASTM A312 is the most prominent standard—applied to welded and seamless stainless steel pipes used in high-temperature, high-pressure, and corrosive environments.

In addition to A312, other relevant ASTM standards include:

- ASTM A269 – for heat-resistant tubes

- ASTM A778 / ASTM A380 – covering surface cleaning and finishing requirements

- ASTM A358 – for electric-fusion-welded stainless steel pipes

The ASTM standard is the most widely used standard for evaluating the quality of stainless steel pipes.

ASTM sets strict requirements for chemical composition (Cr, Ni, Mo…), tensile strength, yield strength, elongation, and surface quality. In particular, the standard requires pipes to undergo heat treatment, polishing, and the complete removal of impurities that could affect passivation.

Thanks to these stringent conditions, stainless steel pipes that meet ASTM standards offer excellent corrosion resistance, minimizing the risk of pitting, cracking, or localized corrosion.

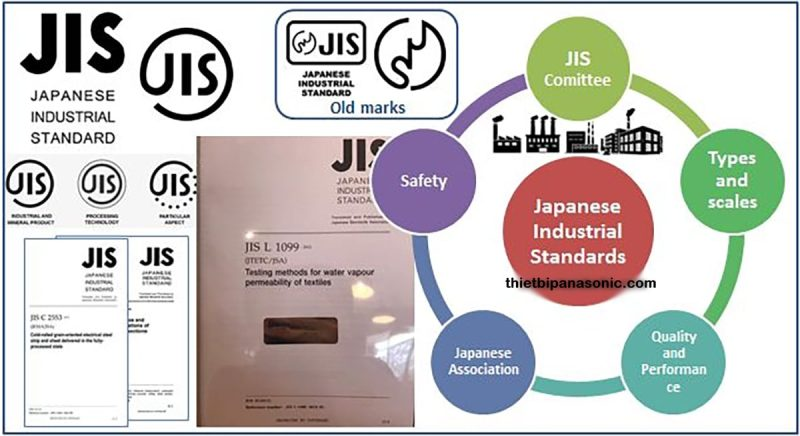

1.2. JIS Standards

JIS (Japanese Industrial Standards) is a system of industrial standards in Japan, managed by the Japanese Industrial Standards Committee (JISC) and published by the Japanese Standards Association (JSA). These standards are known for their high level of strictness and stability in stainless steel manufacturing.

Among them, JIS G3459 is the primary standard applied to welded stainless steel pipes used in industrial applications.

The JIS standard originates from Japan.

This standard clearly defines requirements regarding:

- Dimensions: nominal diameter (DN) and thickness based on Schedule

- Permitted stainless steel grades (e.g., SUS304, SUS304L, SUS316, SUS316L…)

- Mechanical properties and quality inspection procedures

Products manufactured according to JIS G3459 are widely recognized for their excellent corrosion resistance, as they use rigorously certified stainless steel grades 304 and 316. Thanks to the material’s inherent strength and its protective oxide layer, JIS-compliant stainless steel pipes can withstand corrosive environments such as seawater, chemical solutions, and high-temperature steam.

1.3. DIN Standard

The DIN standard was developed by the German Institute for Standardization (DIN) in Berlin. Its primary objective is to establish unified standards for products and manufacturing processes to ensure consistent product quality.

1.4. Additional Corrosion-Resistance Testing

To further enhance the reliability of welded stainless steel pipes in corrosive environments, additional tests are essential in addition to meeting baseline standards.

According to ASTM A312, pipes must be free from scale and may undergo passivation to form a protective oxide layer. After welding and annealing, manufacturers typically perform pickling and chemical immersion treatments to increase the stainless steel’s passivation capability.

Other real-world corrosion tests are commonly applied, such as salt spray testing according to ASTM B117.

Notably, ASTM G48 is the standard method used to evaluate the pitting and crevice corrosion resistance of stainless steels in a concentrated ferric chloride solution. These verification processes help confirm the material’s real-world corrosion resistance under harsh conditions, ensuring that stainless steel pipes do not deteriorate prematurely when put into service.

2. Benefits of Using Welded Stainless Steel Pipes That Meet Corrosion-Resistance Standards

Welded stainless steel pipes that comply with corrosion-resistance standards offer exceptional advantages, clearly distinguishing them from non-certified products.

First, their superior corrosion resistance helps maintain structural integrity over time, minimizing surface pitting, weld cracking, or degradation when exposed to chemical environments or seawater. This is especially critical for outdoor applications, drainage systems, food processing facilities requiring high hygiene standards, and pressure pipelines.

Additionally, certified stainless steel pipes possess higher mechanical strength thanks to precise alloy composition, ensuring reliable load-bearing and compression resistance. Standardized production processes provide strong welds, consistent structure, polished surfaces, and improved aesthetics for architectural applications.

Using certified pipes also brings long-term economic benefits. Although the upfront cost may be higher, reduced maintenance, fewer major repairs, and minimized unexpected failures help businesses save significantly over the entire life cycle of their projects.

It is undeniable that stainless steel pipes offer many outstanding advantages compared to other construction materials.

3. How to Verify Corrosion-Resistance Standards Before Selecting Welded Stainless Steel Pipes

Before purchasing corrosion-resistant welded stainless steel pipes, buyers should carefully check both documentation and actual product quality.

First, review the technical dossier and quality certificates (CO/CQ). These documents must clearly state the steel grade, applicable standards (ASTM A312, JIS G3459, etc.), chemical composition results, and mechanical test results (tensile strength, elongation, etc.). Avoid accepting incomplete files or unclear information.

Next, inspect the physical product with the naked eye. Pipes must have a uniform, bright surface with no rust stains and a smooth, even finish. Welded pipe ends must be flat-ground and treated for anti-corrosion. Several quick on-site tests may also be performed: magnet testing, dilute acid testing (using HCl or dilute nitric acid), or testing alloy composition with a spectrometer.

If possible, investors should request the supplier or a third-party laboratory to conduct advanced corrosion-resistance testing.

4. Reputable Suppliers of Welded Stainless Steel Pipes That Meet Corrosion-Resistance Standards

Choosing a reputable supplier ensures that stainless steel pipes meet required technical and quality standards. Reliable suppliers are typically direct manufacturers or large distributors with robust quality management systems and extensive industry experience. They provide complete documentation such as CO, CQ, and MTC for each shipment, confirming the product’s origin and applicable standards.

When purchasing, customers should prioritize trusted brands with clear information and positive feedback. The more years of experience a supplier has in producing welded stainless steel pipes, the better their capability to ensure compliance with corrosion-resistance standards.

Son Ha SSP stainless steel products are carefully packaged before being delivered to customers.

In the Vietnamese market today, Son Ha SSP is one of the leading reputable manufacturers and suppliers of stainless steel. The company operates two large-scale stainless steel pipe manufacturing plants in Hanoi and Bau Bang, with a total area of up to 70,000 m², fully meeting international standards such as ASTM, JIS, and DIN.

Son Ha SSP’s welded stainless steel pipes not only comply with corrosion-resistance standards but also deliver superior mechanical strength and durability, making them suitable for a wide range of industrial, construction, infrastructure, and outdoor applications.

With more than 25 years of experience in the stainless steel industry, Son Ha SSP has firmly established itself as a trusted partner for major projects. Choosing Son Ha SSP means ensuring that your welded stainless steel pipes truly meet corrosion-resistance standards, offering long-lasting durability while optimizing maintenance and operational costs.

For consultation and detailed quotations, contact the Hotline 1800 6566 or visit the website sonhassp.com.

Adhering to corrosion-resistance standards for welded stainless steel pipes ensures product quality and creates a solid foundation for safe, durable, and cost-efficient system operation. Standards such as ASTM, JIS, along with supplemental testing methods, play a crucial role in evaluating the strength and longevity of welded stainless steel pipes. Understanding and selecting the right products help businesses optimize performance, enhance structural durability, and reduce risks throughout their usage cycle.

⇒ RELATED ARTICLES:

Stainless Steel Welded Decorative Pipes for Luxurious Interior Design

Why should stainless steel welded tubes be chosen for railings and staircases?

Industrial Welded Stainless Steel Pipes for Oil and Gas Pipeline Systems

Next latest post

Safe Stainless Steel Pipe Transportation Process and Important Considerations

What Is a Ø16 Stainless Steel Pipe? Specifications, Classification, and the Latest Price List

Son Ha SSP Is Honored to Receive the BIS Certification (India)