Deciphering the durability of stainless steel

Stainless steel (also known as inox) is one of the most widely used materials in industries and construction thanks to its superior durability, corrosion resistance, and long lifespan. But in reality, is the durability of stainless steel pipes really good? Let’s explore the details with Son Ha SSP in this article!

1. What is the Durability of Stainless Steel?

1.1. Durability of Stainless Steel Material

The durability of a metal material is usually assessed through factors such as:

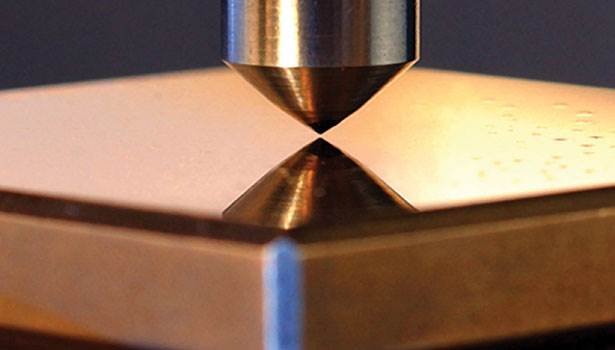

Mechanical properties (tensile strength, hardness, ductility): The mechanical properties of stainless steel are measured through indicators such as:

- Tensile Strength

- Yield Strength

- Elongation

Stainless steel has outstanding durability, hardness, and ductility.

These parameters directly affect the durability of stainless steel in practical applications such as construction, mechanics, and industrial production.

- Corrosion resistance: This is a particularly important characteristic to protect stainless steel pipes in chemical or outdoor environments. Thanks to the protective chromium oxide layer, the lifespan of stainless steel is extended. The higher the chromium content, the more durable the stainless steel is in harsh conditions such as saltwater or strong chemical environments.

- Heat resistance: Some types of stainless steel such as 304 stainless steel can withstand temperatures up to 870 – 925°C, while 316 stainless steel can operate well in higher temperature environments. For applications requiring special heat resistance, stainless steel containing molybdenum or titanium helps enhance heat resistance and prevent oxidation at high temperatures.

1.2. Are Stainless Steel Pipes Durable?

Stainless steel pipes are one of the most durable materials today, notable for their high durability thanks to their special alloy structure. The main components include 10.5% – 30% chromium, which helps create a protective oxide film, preventing oxidation and rust.

In addition, high nickel content (depending on the type of stainless steel) increases ductility and load-bearing capacity, helping stainless steel maintain superior durability over time. As a result, compared to other metals such as carbon steel or aluminum, stainless steel pipes are not only more durable but also have better corrosion resistance, suitable for many harsh environments.

2. Factors Affecting the Durability of Stainless Steel Pipes

2.1. Alloy Composition

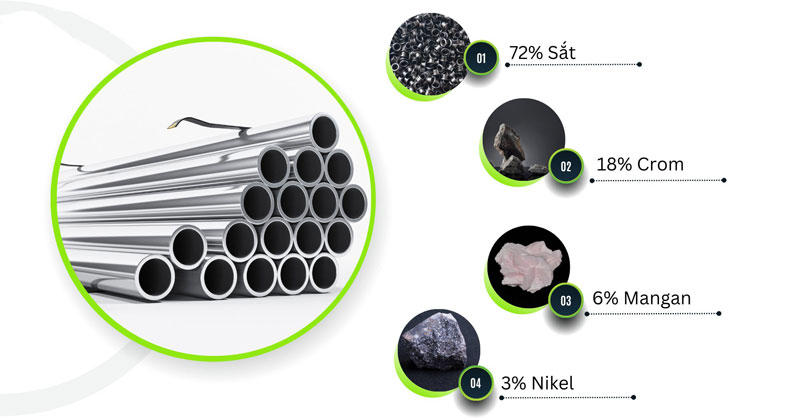

The composition of the alloy determines whether the stainless steel is durable. Each type of stainless steel has its own characteristics, suitable for different applications.

Stainless steel composition includes Fe, Cr, Mn, Ni…

Below is the durability of common stainless steels:

- 201 Stainless Steel: High mechanical strength but less corrosion resistant than 304 stainless steel.

- 304 Stainless Steel: The most common type of stainless steel, with high durability and good rust resistance in normal environments.

- 316 Stainless Steel: Contains additional molybdenum (Mo), which increases chemical corrosion resistance, especially in seawater environments.

- 430 Stainless Steel: Belonging to the Ferritic stainless steel line, with medium durability, mainly used in interiors.

2.2. Mechanical Stress

The load-bearing capacity of stainless steel is determined through tensile strength and yield strength. These indicators help assess the durability of stainless steel in different usage environments. Here are some typical figures:

- 304 Stainless Steel: Tensile strength about 515 MPa, yield strength about 205 MPa.

- 316 Stainless Steel: Tensile strength about 579 MPa, yield strength about 290 MPa.

- 201 Stainless Steel: Tensile strength about 515 MPa, but lower rust resistance than 304 stainless steel.

MPa stands for Megapascal, a unit of pressure measurement in the SI measurement system.

1 Megapascab= 1.000.000 Pascal (Pa)

2.3. Heat Resistance

Heat resistance is an important factor when stainless steel is used in high-temperature applications. Here are the heat resistance levels of some common stainless steels:

- 304 stainless steel withstands heat up to 870°C – 925°C without oxidation.

- 316 stainless steel can withstand heat better in harsh environments.

- 430 stainless steel has lower heat resistance, easily discolored when exposed to high temperatures.

2.4. Corrosion Resistance

Stainless steel pipes have high corrosion resistance thanks to the protective chromium oxide film. However, depending on the usage environment, the level of durability may vary. Some environments that affect the durability of stainless steel include:

- Acidic environment: 316 stainless steel is more suitable than 304 stainless steel due to molybdenum’s corrosion resistance.

- Saltwater environment: 316 or 2205 stainless steel should be used to avoid rust.

- Outdoor environment: 304 stainless steel is a suitable choice with high durability and reasonable cost.

3. Comparison of Stainless Steel Durability with Other Materials

| Material Type | Tensile Strength (MPa) | Corrosion Resistance | Applications |

| 316 Stainless Steel | 579 – 700 | Very high | Medical, chemical, marine |

| 304 Stainless Steel | 515-620 | High | Construction, interior, food |

| Aluminum | 90 – 290 | Medium | Mechanics, automotive |

| Carbon Steel | 400-550 | Low | Construction structures |

Based on the above analysis, it can be confirmed that the durability of stainless steel pipes is very high, superior to many other metal materials. Contact Son Ha SSP immediately via hotline 1800 6566 for advice and competitive quotes as soon as possible!

⇒ See more: Common types of stainless steel pipes currently available

Next latest post

Safe Stainless Steel Pipe Transportation Process and Important Considerations

What Is a Ø16 Stainless Steel Pipe? Specifications, Classification, and the Latest Price List

Son Ha SSP Is Honored to Receive the BIS Certification (India)