Comparison: Cold Rolled Stainless Steel Coils (Thickness 0.3–3mm) vs. Other Stainless Steel Coil Types

Cold Rolled Stainless Steel Coils with a thickness range of 0.3–3mm are premium-grade materials characterized by their smooth, bright surface finish, high dimensional accuracy, and excellent corrosion resistance.

Thanks to their durability, aesthetic appeal, and ease of fabrication, these coils are widely used across industrial manufacturing, construction, and interior decoration.

This article outlines the key differences, advantages, and specific applications of cold rolled stainless steel coils (0.3–3mm) compared to other coil types—helping you make well-informed and effective investment decisions.

1. Overview of Cold Rolled Stainless Steel Coils

Cold Rolled Stainless Steel Coil is a product made from hot rolled stainless steel that has undergone cold rolling at low temperatures to reduce thickness and improve surface quality.

During this process, the steel passes through multiple rolling stands under high pressure, achieving precise thickness, smooth glossy finish, and enhanced hardness.

Common Specifications:

- Thickness: 0.3mm – 3mm

- Width: 600mm – 1500mm (depending on manufacturer)

- Surface Finishes: 2B, BA, No.4, HL, Mirror (depending on technical or aesthetic requirements)

- Materials / Grades: Common stainless steel grades such as SUS 201, 304, 316, 430, etc.

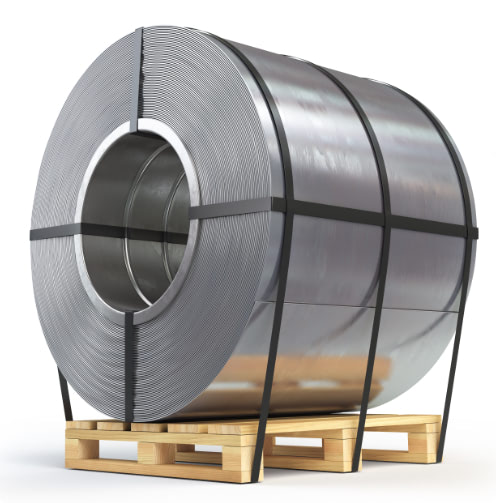

Cold Rolled Stainless Steel Coil (Thickness 0.3–3mm)

Cold Rolled Stainless Steel Coil (Thickness 0.3–3mm)

Cold rolled stainless steel coils with a thickness of 0.3–3mm possess numerous outstanding advantages, making them a top choice in many manufacturing industries. With their thin and flexible structure, these coils are easy to bend, cut, and form, making them ideal for precision components that require tight dimensional tolerances.

Their bright, smooth, and flat surface provides excellent aesthetic value and can be polished to a perfect mirror finish. Thanks to a meticulous surface treatment process, the material offers excellent corrosion resistance, minimizing oxidation even in harsh environments.

Moreover, dimensional stability in cold rolled coils is extremely high, with negligible thickness deviation, perfectly meeting the requirements of automated production lines.

Common Applications of Cold Rolled Stainless Steel Coils (0.3–3mm):

- Interior and exterior decoration, elevators, and household appliances

- Automotive, electronics, and industrial machinery components

- Manufacturing decorative and industrial stainless steel tubes

- Projects requiring high aesthetic quality and precision dimensions

2. Difference Between Cold Rolled and Hot Rolled Stainless Steel Coils

To fully understand the value of cold rolled stainless steel coils, it is essential to distinguish them from hot rolled stainless steel coils (Hot Rolled Stainless Steel Coil) — a type of steel produced at temperatures above 1,000°C.

Comparison Between Hot Rolled Steel and Cold Rolled Steel

Comparison Table Between Hot Rolled and Cold Rolled Coils

| Criteria | Hot rolled coil | Cold Rolled Coil |

| Rolling temperature | Above 1000°C |

Below 200°C |

| Procedure | Rough rolling → cooling → re-rolling | Based on hot rolled steel → pickling → repeated cold rolling → annealing → polishing |

| Surface | Rough, dull, uneven | Shiny, smooth, uniform |

| Thickness | 3mm – 50mm | 0,3mm – 3mm |

| Dimensional accuracy | Lower | Higher, smaller error |

| Hardness and mechanical properties | Lower | Higher due to cold deformation |

| On the surface | Mirror-polished corrugated surface, easy to plate or paint | Rough, grayish-blue or blue-black in color |

| About the application | Steel structure, frame, floor plate, thick pipe. | Household appliances, medical equipment, furniture, decoration, precision mechanical components |

3. Comparison of Cold Rolled Stainless Steel Coils (0.3–3mm) Among Different Stainless Steel Grades

Each stainless steel grade has its own chemical composition and properties, affecting its strength, corrosion resistance, and cost. Below is a detailed comparison of the three most commonly used grades: 201, 304, and 316.

3.1. Cold Rolled Stainless Steel Coil – Grade 201

Stainless steel 201 belongs to the Austenitic group and contains a low nickel content (around 4–5%), making it significantly more affordable than stainless steel 304.

This type stands out for its high strength and hardness, though its corrosion resistance is more limited due to the lower chromium and nickel content.

Because of these characteristics, 201 cold rolled stainless steel coils are typically used in applications that do not require extreme corrosion resistance or long service life but still need aesthetic appeal and mechanical strength.

This grade is ideal for manufacturing household appliances, furniture, basic mechanical parts, and indoor decorative products.

In practice, stainless steel 201 is widely used in sinks, kitchenware, washing machines, window and door frames, etc., thanks to its low cost and easy formability.

However, it is not recommended for outdoor or high-humidity, chemical environments, as it is prone to oxidation and rust.

3.2. Cold Rolled Stainless Steel Coil – Grade 304

Stainless steel 304 is the most widely used Austenitic grade, containing approximately 18–20% Chromium (Cr) and 8–10% Nickel (Ni).

Thanks to its higher nickel content, 304 cold rolled stainless steel coils offer superior corrosion and oxidation resistance, significantly outperforming grade 201.

Additionally, 304 stainless steel features excellent ductility, weldability, and formability, making it suitable for high-precision products that require strict hygiene standards.

It is commonly used in the production of stainless steel water tanks, kitchen equipment, premium household goods, and high-end interior décor components.

3.3. Cold Rolled Stainless Steel Coil – Grade 316

Stainless steel 316 is a premium Austenitic grade, enhanced with 2–3% Molybdenum (Mo).

This addition gives 316 cold rolled coils outstanding overall corrosion resistance compared to 304, especially in chloride-rich environments such as seawater or strong chemical exposure.

The presence of Molybdenum helps prevent pitting and crevice corrosion, while maintaining high ductility, weldability, and formability.

With excellent mechanical strength and oxidation resistance, 316 is considered an ideal material for harsh working environments and technically demanding applications.

In reality, stainless steel 316 is widely used in chemical processing, food and pharmaceutical equipment manufacturing, marine industries, and other sectors that require high safety, hygiene, and durability.

Typical applications include food processing machinery, beverage systems, medical instruments (such as surgical tools and implant screws), aircraft components, chemical tanks, and equipment for oil and nuclear industries.

However, since 316 cold rolled stainless steel is considerably more expensive, it should be chosen when exceptional corrosion resistance and maximum durability are truly required.

4. Which Type of Stainless Steel Coil with a Thickness of 0.3–3mm Should You Choose?

Selecting the appropriate stainless steel coil depends on factors such as the usage environment, technical requirements, and budget.

| Need for use | Recommended stainless steel coil type | Reason for choosing |

| Interior, home decoration | Cold rolled stainless steel 201 | Cheap, easy to process, bright surface |

| Household appliances, high-end furniture, panels, elevators | Cold rolled stainless steel 304 | Durable, bright, good corrosion resistance, easy to clean |

| Marine environment, chemical industry, harsh outdoors | Cold rolled stainless steel 316 | Maximum rust resistance, long life |

In addition, when selecting cold rolled stainless steel coils with a thickness of 0.3–3mm, you should pay attention to the origin and quality of the product.

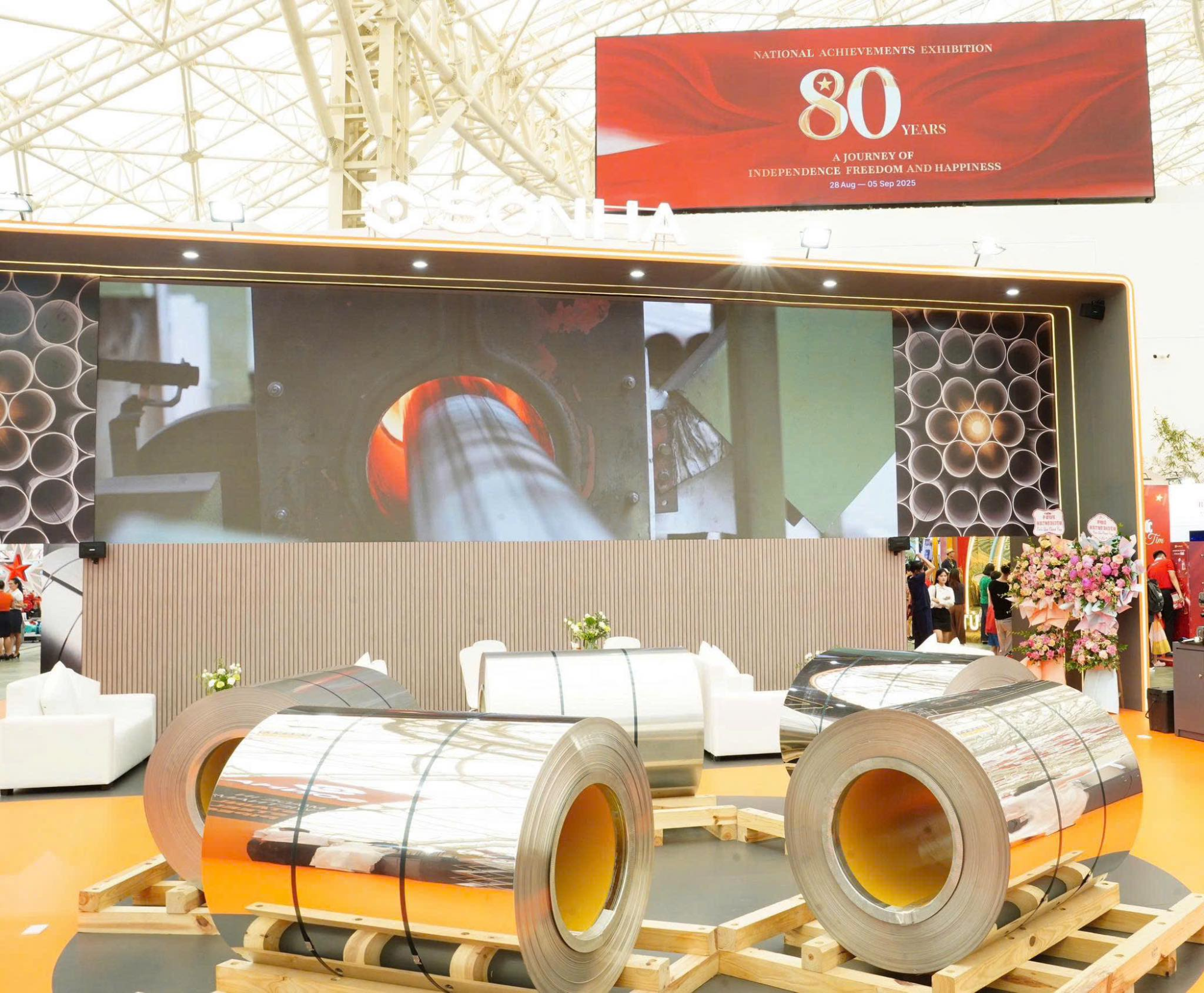

It is advisable to prioritize manufacturers with modern cold rolling lines and clear quality certification, such as Son Ha SSP.

In Vietnam, Son Ha SSP is one of the pioneering companies equipped with a fully integrated production system, advanced imported technology, and a strict quality control process, ensuring that each stainless steel coil meets international standards and fully satisfies the requirements of both domestic and global markets.

Son Ha SSP cold rolled stainless steel coil

Conclusion

Cold rolled stainless steel coils with a thickness of 0.3–3mm are the ideal choice for applications requiring high precision, excellent aesthetics, and superior corrosion resistance.

However, to ensure the quality of the final product, businesses should choose reputable suppliers that meet clear technical standards and possess comprehensive quality certifications.

With its advanced cold rolling production lines, strict quality control procedures, and experienced technical team, Sơn Hà SSP proudly delivers international-standard cold rolled stainless steel coils that are bright, durable, and of outstanding quality.

> RELATED ARTICLES:

Applications of Cold-Rolled Stainless Steel Coils in the Automotive Industry

Exploring High-Quality Stainless Steel Coils: Features, Applications, and Trusted Suppliers

https://sonhassp.com/en/explore-the-latest-prices-of-industrial-stainless-steel-pipes/

8mm Rebar Coil: Features, Advantages, and Applications

Latest Decorative Stainless Steel Welded Pipe Prices And Detailed Information

Next latest post

Safe Stainless Steel Pipe Transportation Process and Important Considerations

What Is a Ø16 Stainless Steel Pipe? Specifications, Classification, and the Latest Price List

Son Ha SSP Is Honored to Receive the BIS Certification (India)