Applications of Cold-Rolled Stainless Steel Coils in the Automotive Industry

In the modern automotive industry, materials play an extremely important role in determining the durability, performance, and aesthetics of vehicles. Among them, cold-rolled stainless steel coils are one of the most widely used materials thanks to their excellent corrosion resistance, high dimensional accuracy, and smooth, attractive surface finish.

This article will help you better understand the applications of cold-rolled stainless steel coils in the automotive industry, as well as some key considerations when processing this material.

1. Common Applications of Cold-Rolled Stainless Steel Coils in the Automotive Industry

In automobile manufacturing, every component requires materials with high precision and optimal durability. Cold-rolled stainless steel coils possess superior strength, corrosion resistance, and a refined appearance—making them ideal for many critical automotive parts. Specifically:

1.1 Exhaust Systems and Heat-Resistant Components

One of the most common applications of cold-rolled stainless steel coils is in automotive exhaust systems. Exhaust pipes must withstand high temperatures, exhaust gases, and highly corrosive environments.

Typical stainless steel grades used for exhaust systems, connectors, manifolds, and mufflers include:

- Stainless Steel 409L: Offers good heat resistance up to 675°C, excellent oxidation resistance, and cost-effectiveness.

- Stainless Steel 439: Improved weldability and enhanced corrosion resistance under humid conditions.

- Stainless Steel 304: Used in premium vehicles requiring longer service life and exceptional wear resistance.

Thanks to their smooth cold-rolled surface, these coils help minimize soot buildup, improve exhaust flow, reduce fuel consumption, and increase engine efficiency.

Cold-Rolled Stainless Steel Coils Used for Exhaust Systems in Automotive Manufacturing

1.2. Body, Frame, and Exterior Decorative Components

With its glossy surface, high mechanical strength, and excellent formability, cold-rolled stainless steel is widely used for exterior decorative parts such as:

door trims, mudguards, handles, logos, mirror covers, and front grilles.

Some premium car models use cold-rolled 304L stainless steel for the A-, B-, and C-pillars to create a luxurious highlight, prevent rust, and withstand harsh weather conditions.

Additionally, this material is applied in subframes or underbody protection panels, where rigidity and impact resistance are essential.

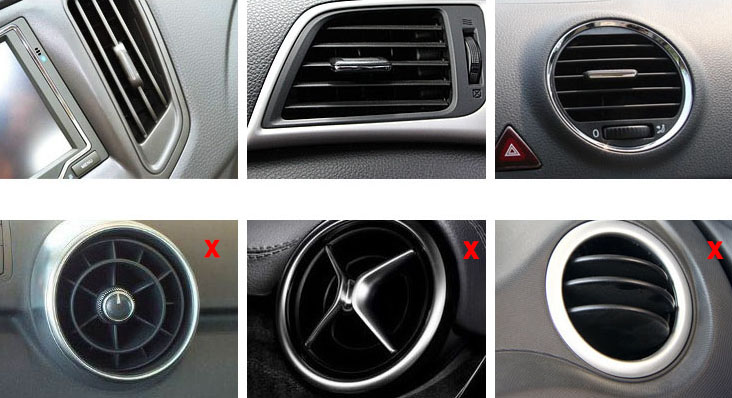

1.3. Interior Components and Precision Mechanical Parts

Inside the vehicle, cold-rolled stainless steel coils are found in components that require high precision and aesthetic appeal, including: dashboard trims, trunk frames, and door covers.

They are also used in the core structures of control mechanisms, seat slide rails, and small friction-bearing components.

Beyond these common uses, cold-rolled stainless steel coils are also applied in battery cooling systems, lightweight structural frames, and electronic module protection plates, highlighting their growing importance in the modern automotive industry.

The Small Details That Define a Car’s Beauty

2. Why the Automotive Industry Uses Cold-Rolled Stainless Steel Coils

2.1. Exceptional Corrosion Resistance

In real-world operating conditions, vehicles are constantly exposed to moisture, road salt, dust, car-wash chemicals, and even mild acids present in the atmosphere. These are all factors that can easily cause corrosion and oxidation.

For this reason, manufacturers prefer to use cold-rolled stainless steel coils due to their naturally superior corrosion resistance—especially in grades such as 304L, 316L, and 409L.

The surface of cold-rolled stainless steel forms an extremely thin yet strong chromium oxide (Cr₂O₃) film, which acts as a protective barrier against oxidation. Remarkably, this layer can self-heal when lightly scratched, maintaining the metal’s integrity and appearance.

As a result, stainless steel components retain their bright, clean finish and rust-free quality even under the most demanding environmental conditions.

Cold-Rolled Stainless Steel Coil

Compared to Carbon Steel or Galvanized Steel The lifespan of cold-rolled stainless steel coils is 3–5 times longer than that of carbon or galvanized steel. At the same time, they significantly reduce maintenance and replacement costs.

This is why the material is often referred to as a “durable shield”, enhancing both the longevity and reliability of the entire vehicle structure.

2.2. Higher Tensile Strength than Hot-Rolled Steel

Compared to hot-rolled steel, cold-rolled stainless steel has a 20–30% higher yield strength and tensile strength, providing superior load-bearing capability and better deformation resistance in collisions.

As a result, manufacturers can use thinner sheets without compromising rigidity, which helps reduce vehicle weight, improve fuel efficiency, and lower CO₂ emissions—all crucial factors in modern automotive design.

2.3. Aesthetic Appeal and Surface Finish Versatility

Beyond its mechanical properties, appearance and surface finish quality are key reasons why cold-rolled stainless steel coils are highly favored in today’s automotive industry.

Thanks to their smooth, flat surface and high dimensional accuracy, these coils can be finished in a wide variety of textures to match specific design needs:

- 2B Finish: Smooth, bright surface ideal for painting or chrome plating; commonly used for visible exterior parts requiring additional coating.

- BA / 8K Finish: Mirror-like reflective surface with a premium appearance—perfect for decorative trims, logos, handles, and interior covers.

HL (Hairline) Finish: Fine, brushed texture offering a sophisticated light effect and elegant aesthetic highlights for both interior and exterior automotive components.

A bright, smooth surface is one of the key factors that make cold-rolled stainless steel coils widely used in the automotive industry.

2.4. Easy Forming, Bending, Cutting, and Welding

Although harder than hot-rolled steel, cold-rolled stainless steel coils still offer excellent formability.

With today’s advanced 3D stamping and bending technologies, stainless steel can be shaped into complex components such as covers, frames, panels, and brackets while maintaining strong structural integrity.

2.5. Compliance with International Technical Standards

Most cold-rolled stainless steel coils used in the automotive industry today meet strict global technical standards, including:

- ASTM A240 / A480 (USA): Specifies chemical composition, tensile strength, and surface finish requirements for stainless steel sheets and coils.

- JIS G4305 (Japan): Regulates thickness, flatness, and corrosion resistance—commonly applied to automotive components across Asian markets.

- EN 10088-2 (Europe): Defines mechanical properties, weldability, and durability under harsh environments.

Thanks to this compliance, the material can be seamlessly integrated into global supply chains, ensuring uniform quality for both exported components and finished vehicles.

3. Common Challenges in Processing (Bending, Cutting, Welding) Cold-Rolled Stainless Steel

Despite its numerous advantages, the processing of cold-rolled stainless steel coils poses several technical challenges.

Because of its higher hardness and yield strength compared to hot-rolled steel, operations such as bending, cutting, welding, and handling require strict process control to ensure final product quality.

Bending and Forming

During bending and stamping, the high hardness of cold-rolled stainless steel can lead to springback or edge cracking at sharp angles.

To prevent this, technicians must:

- Precisely calculate the minimum bending radius based on the steel grade,

- Use high-precision dies with proper lubrication,

- Maintain a slow pressing speed, and

- Preheat the material slightly for parts requiring larger curvature, achieving the necessary ductility without affecting the surface finish.

Cutting and Slitting

When cutting or slitting, the smooth, mirror-like surface of cold-rolled stainless steel is prone to scratches, burrs, and sharp edges if mishandled.

To avoid this, specialized cutting techniques are applied, followed by edge cleaning and inspection to prevent surface defects in subsequent manufacturing stages.

Welding

Welding is the most technically demanding process for cold-rolled stainless steel.

The high heat generated during welding can destroy the protective chromium oxide (Cr₂O₃) film, and if the temperature exceeds 425°C or is unevenly distributed, oxidation and strength loss may occur.

To counter this, welders should:

- Use argon or helium shielding gas with TIG/MIG welding,

- Control the heat input carefully, and

- Perform post-weld cleaning or pickling to restore the protective oxide layer.

By mastering these processes, manufacturers can fully harness the potential of cold-rolled stainless steel coils—ensuring durability, precision, and aesthetic quality in every automotive component.

Conclusion

With its outstanding corrosion resistance, high precision, and superior surface finish, cold-rolled stainless steel coil has become a standard material in the modern automotive industry.

From exhaust systems and vehicle bodies to decorative trims and precision mechanical parts, cold-rolled stainless steel enhances durability, reduces weight, improves aesthetics, and boosts overall performance.

If your business is seeking a reliable, internationally certified, and cost-effective supplier of cold-rolled stainless steel coils, Son Ha SSP Vietnam is your trusted partner for expert consultation and the most competitive quotations.

Related Articles:

Exploring High-Quality Stainless Steel Coils: Features, Applications, and Trusted Suppliers

Explore the latest prices of industrial stainless steel pipes.

Next latest post

Safe Stainless Steel Pipe Transportation Process and Important Considerations

What Is a Ø16 Stainless Steel Pipe? Specifications, Classification, and the Latest Price List

Son Ha SSP Is Honored to Receive the BIS Certification (India)