A Detailed Overview of the Characteristics and Applications of Welded Stainless Steel Pipes

Welded stainless steel pipes have become a core material in modern engineering systems, industrial structures, and infrastructure projects. With a combination of mechanical strength, corrosion resistance, and long-term stability, this type of pipe meets the stringent standards set by engineers, contractors, and business owners. In the article below, Son Ha SSP provides a comprehensive overview of the characteristics, structure, applications, and selection criteria for high-quality welded stainless steel pipes suitable for different types of projects.

1. What Are Welded Stainless Steel Pipes?

1.1. Definition and Structure of Welded Stainless Steel Pipes

Welded stainless steel pipes (also known as welded stainless pipes) are pipes manufactured from stainless steel using advanced welding methods. Stainless steel is an iron-based alloy containing at least 10.5% chromium, which forms a passive oxide layer on the surface, giving the pipe excellent corrosion resistance.

The structure of the pipe consists of two main components: the pipe body and the weld seam. The pipe body is responsible for rigidity and load-bearing capacity, while the weld seam determines stability, tightness, and corrosion resistance. With the development of TIG, plasma, and laser welding technologies, the weld seams of modern welded stainless steel pipes now have strength nearly equivalent to the base material, ensuring continuity and stability during operation.

Welded stainless steel pipes are manufactured using advanced welding methods.

1.2. Distinguishing Between Welded Stainless Steel Pipes and Seamless Stainless Steel Pipes

Although both are made from stainless steel, welded stainless steel pipes and seamless stainless steel pipes differ significantly in manufacturing technology and applications. Seamless stainless steel pipes are produced by extrusion or hot drawing processes and contain no weld seam, allowing them to withstand very high pressure and making them suitable for extremely demanding working environments such as oil and gas systems, high-pressure applications, or high-temperature conditions.

In contrast, welded stainless steel pipes offer clear advantages in terms of cost efficiency, a wide range of sizes, mass production capability, and superior surface finish. Thanks to modern welding technologies, the strength of the weld seam is now nearly equivalent to that of seamless pipes in most common civil and industrial applications. As a result, welded stainless steel pipes have become a primary choice in many fields due to their optimal balance between performance and cost.

Seamless Stainless Steel Pipe

2. Five Outstanding Advantages of Welded Stainless Steel Pipes

2.1. High Mechanical Strength and Solid Structure

One of the main reasons welded stainless steel pipes are widely used in engineering systems is their excellent load-bearing capacity. Thanks to stable alloy composition and standardized manufacturing processes, these pipes can withstand heavy loads and resist deformation under pressure or fluctuating temperatures.

In particular, stainless steel grade 304—one of the most common materials for welded pipes—offers high tensile strength and good impact resistance, ensuring the piping system maintains its shape and stability even in harsh working environments. The structure of welded stainless steel pipes is well suited for medium-pressure systems such as steam lines, compressed air systems, technical pipelines, and industrial framework structures. As a result, the durability and safety of the entire system are ensured over the long term.

2.2. Superior Corrosion Resistance

Oxidation resistance is one of stainless steel’s most notable characteristics. With a minimum chromium content of 10.5%, the material can form a passive oxide layer on the surface when exposed to air. This layer protects the pipe against mild acids, alkaline environments, salt, and high humidity.

In practice, welded stainless steel pipes rarely rust when used outdoors or in industrial environments containing corrosive agents. With strictly controlled welding processes, weld quality can reach a level comparable to solid stainless steel, ensuring high stability and tightness. This makes welded stainless steel pipes a reliable choice for food processing, pharmaceuticals, clean water systems, and light chemical industries.

2.3. Lightweight and Easy to Fabricate

Another major advantage of welded stainless steel pipes is their light weight and high flexibility in fabrication. Compared with cast iron pipes or thick-walled carbon steel pipes, welded stainless steel pipes have a lower density, making transportation and installation easier. Cutting, bending, polishing, and fitting with accessories are also simple, significantly reducing construction time.

2.4. High Aesthetic Value (Surface Gloss and Smoothness)

In addition to meeting technical requirements, welded stainless steel pipes also offer high aesthetic value. Their surfaces are bright, smooth, and uniform thanks to post-welding polishing processes. This makes the weld seam almost invisible, providing an elegant appearance for interior, architectural, or decorative applications that require a high level of visual appeal.

Stainless steel 304 with standard 2B finish or mirror-polished No.8 finish is a typical example of excellent surface quality and superior finishing capability. Moreover, the smooth stainless steel surface is easy to clean and minimizes dust accumulation and discoloration during use.

2.5. High Stability and Long Service Life

Thanks to excellent mechanical properties and corrosion resistance, welded stainless steel pipes remain stable under various working conditions. The products are highly resistant to oxidation and environmental exposure, especially when using stainless steel 316. Combined with good mechanical strength, this results in a long service life with minimal need for replacement.

In addition, welded stainless steel pipes are easy to maintain: they rarely stain, attract dirt, or require special cleaning agents. This stability ensures reliable long-term operation of piping systems, maintains performance over time, and reduces maintenance and repair costs in the long run.

3. Common Types of Welded Stainless Steel Pipes on the Market

3.1. Classification by Steel Grade

Welded stainless steel pipes are manufactured from various steel grades to meet different technical requirements and operating environments. The most common grades are stainless steel 304 and 304L, favored for their good corrosion resistance, high durability, and reasonable cost. These grades are widely used in water supply systems, gas pipelines, structural applications, and many industrial uses.

For harsher environments such as chemical plants, coastal areas, or locations with high chloride content, stainless steel 316 and 316L are optimal choices. The added molybdenum significantly enhances resistance to localized corrosion, particularly crevice corrosion and pitting.

In addition, some residential or decorative applications use stainless steel T201 to reduce costs while still ensuring basic strength. For more specialized requirements, grades such as 430, 310S, and 904L are also used, though they are less common due to higher costs and specific application purposes.

3.2. Classification by Shape

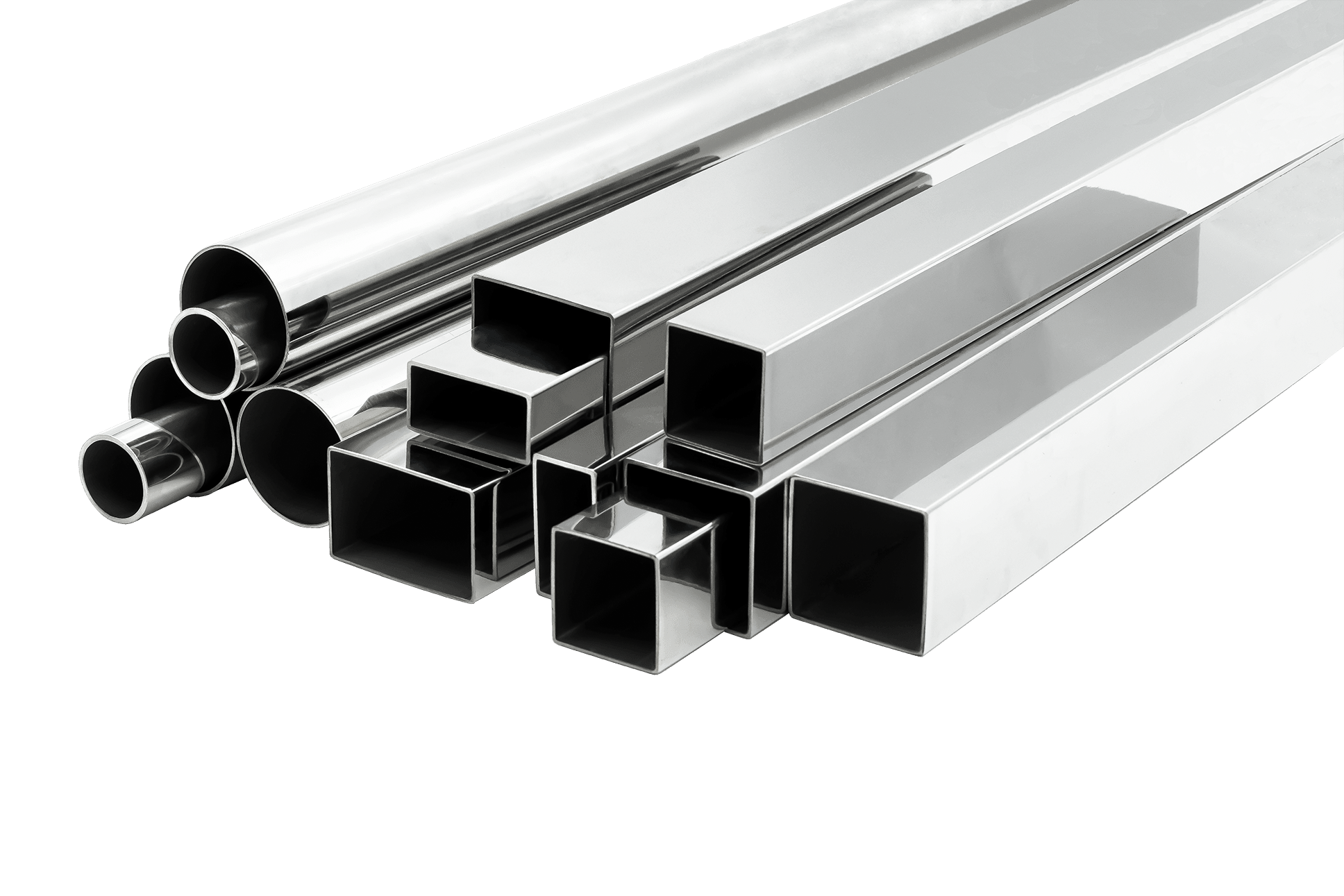

In terms of shape, welded stainless steel pipes are divided into two main groups: round pipes and box (rectangular/square) pipes.

- Round pipes are the most common type, used in liquid and gas transmission systems, as well as for frames and load-bearing structures. They provide stable performance and are easy to connect with standard fittings.

Square and Rectangular Hollow Sections stainless steel pipes, including square and rectangular forms, are produced by welding stainless steel sheets. With angular cross-sections and an aesthetically pleasing appearance, these pipes are widely used in architecture, interior design, railings, fences, and decorative elements. Box pipes are available in various sizes, making them suitable for projects ranging from residential to commercial construction.

welded-stainless-steel-pipe

3.3. Classification by Surface Finish Quality

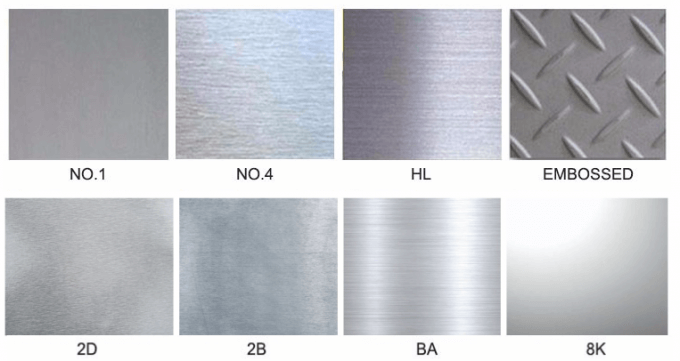

The surface finish quality of welded stainless steel pipes directly affects both their aesthetic appearance and operational performance. Depending on the requirements of each industry, stainless steel pipes can be manufactured with different levels of surface polishing.

The Bright Annealed (BA) finish provides a highly glossy, smooth, and clean surface, and is commonly used in medical applications, food processing, and high-end decorative purposes. The standard 2B finish offers moderate brightness with a slightly smooth texture and is widely applied across industrial sectors due to its versatility. For projects where aesthetics are not a primary concern, the 2D finish is a more economical option, characterized by a lower level of gloss.

Stainless Steel PipeSurface-Finishes-from-No-1-to-8K

In addition, the No.4 surface features fine, matte brush lines, making it suitable for modern interiors or stainless steel railings. The No.8 finish delivers a premium mirror-like effect and is preferred in architectural decoration where elegance and luxury are required. Thanks to this wide variety of surface finishes, welded stainless steel pipes can meet both technical requirements and design aesthetics across many different types of projects.

4. Frequently Asked Questions About Welded Stainless Steel Pipes

4.1. In Which Fields Are Welded Stainless Steel Pipes Used?

With the combination of high mechanical strength, excellent corrosion resistance, and hygienic safety, welded stainless steel pipes are widely used across many technical fields. In the chemical and oil & gas industries, they are trusted for systems that transport corrosive substances or operate under high pressure, where materials must withstand harsh working environments.

In the food and beverage industry, clean water supply, and wastewater treatment, welded stainless steel pipes help ensure hygiene and minimize contamination thanks to stainless steel’s corrosion resistance and smooth surface.

The construction, industrial, and energy sectors also use welded stainless steel pipes in systems such as fire protection, ventilation, and steam distribution, as the material offers heat resistance and long-term corrosion protection. Notably, industries with strict requirements—such as medical equipment manufacturing and aerospace—also apply welded stainless steel pipes for components that must maintain stability and withstand high pressure and temperature.

Welded stainless steel pipes are widely used in water supply systems

4.2. How to Choose High-Quality Welded Stainless Steel Pipes

To select high-quality welded stainless steel pipes, engineers or business owners should consider factors such as steel grade, wall thickness, manufacturing standards, weld quality, surface finish, and accompanying certifications. In addition, choosing a reputable manufacturer with strict quality control capabilities is essential to ensure durability and safety during use.

4.3. A Reputable Supplier of Welded Stainless Steel Pipes

Selecting the right materials from the design stage directly determines the durability and investment efficiency of any infrastructure project. In this regard, welded stainless steel pipes from Son Ha SSP are considered an optimal solution for modern infrastructure works thanks to their outstanding load-bearing capacity, high stability, and excellent corrosion resistance under all environmental conditions.

Compared to other suppliers on the market, Son Ha SSP offers several outstanding advantages:

- Product quality certified to international PED standards, ensuring stability and safety in projects with strict technical requirements.

- Welded stainless steel materials with high hardness and tensile strength, strictly controlled by automated machinery systems to ensure uniform quality across every meter of pipe.

- Superior corrosion resistance, especially in outdoor environments, coastal areas, or regions exposed to chemicals.

- High surface gloss that limits dirt adhesion, enhancing aesthetics and reducing cleaning and maintenance costs.

Strong in-house manufacturing capacity with two large factories covering up to 70,000 m² and 200 production lines, ensuring consistent supply and on-time delivery.

Son Ha SSP Manufacturing Plant and Production System

Choosing Son Ha SSP means optimizing the lifecycle cost of your project, minimizing technical risks, and enhancing the durability of structural systems. If you are looking for standard-compliant welded stainless steel pipe solutions for bridge, road, and infrastructure projects, please contact Son Ha SSP via Hotline 1800 6566 or visit sonhassp.com.

Welded stainless steel pipes offer many outstanding advantages, effectively meeting technical, aesthetic, and durability requirements across a wide range of industrial and civil applications. This material is increasingly becoming the optimal choice for many businesses and engineers involved in critical projects.

>> RELATED ARTICLES:

SON HA INDUSTRIAL STAINLESS STEEL PIPES – THE PERFECT SOLUTION FOR EVERY PROJECT

Son Ha SSP Vietnam Shines at the World Stainless Steel Conference & Exhibition 2025 – Netherlands

Overview of Corrosion-Resistance Standards for Stainless Steel Welded Pipes

Stainless Steel Welded Decorative Pipes for Luxurious Interior Design

Next latest post

Safe Stainless Steel Pipe Transportation Process and Important Considerations

What Is a Ø16 Stainless Steel Pipe? Specifications, Classification, and the Latest Price List

Son Ha SSP Is Honored to Receive the BIS Certification (India)